Hi

@chrisko, thank you for your reply.

Erich didn't run into the issue in the article - he tried a big a and simple shape. It's easier to separate long line with small uncut portion then very short line with uncut portion. Besides, there is already a comment with the same problem under the article there without reply

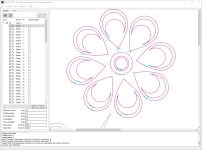

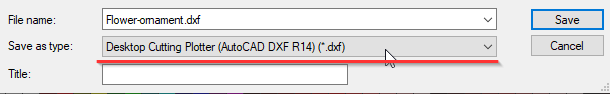

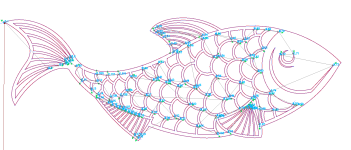

I was going through some testing with it, and this is what I come up with.

Seems like the gaps in lines are related to where cut path starts/ends. Meaning it is not optimized for corners/peaks.

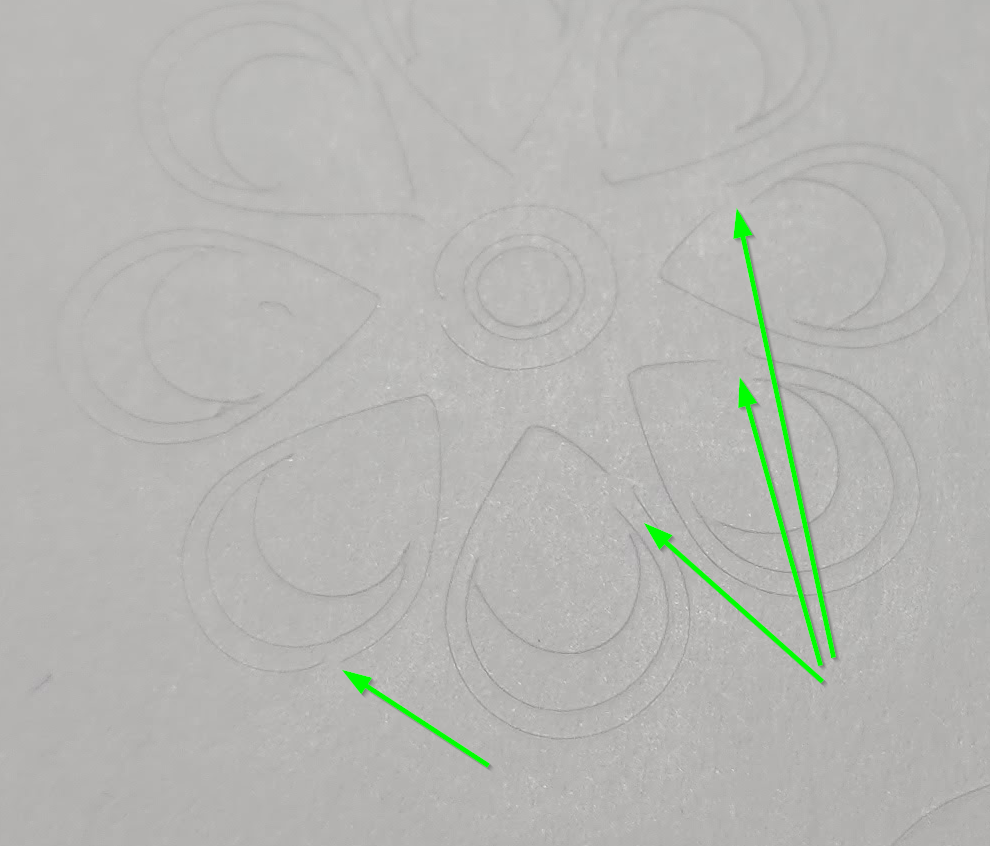

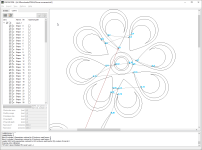

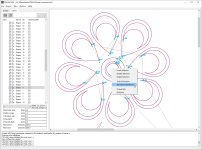

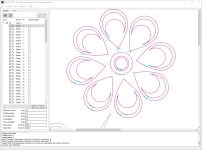

When I just load the file,

without optimization this is how it looks like (zoomed in).

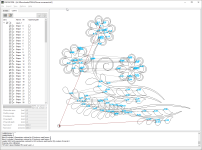

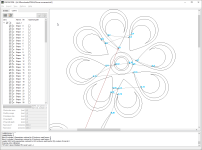

Then, with

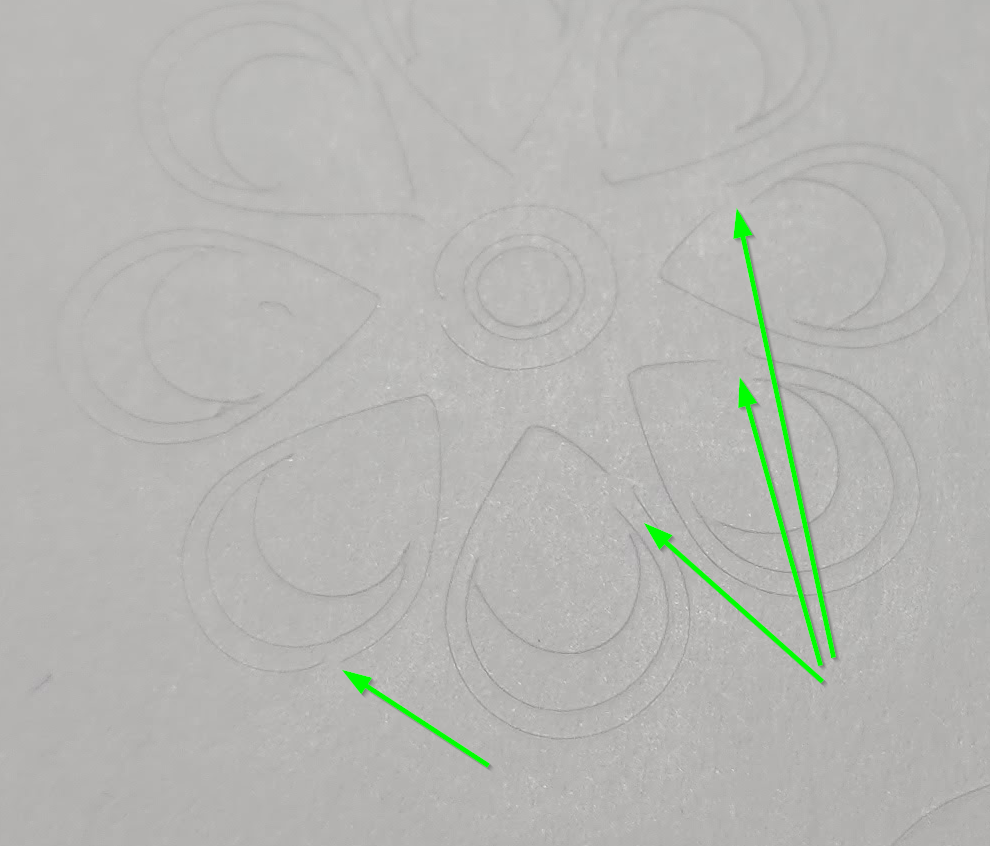

turned off TSP, optimized tool path looks like this:

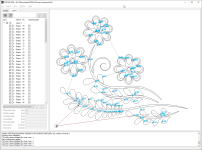

Then with TSP optimization ON -

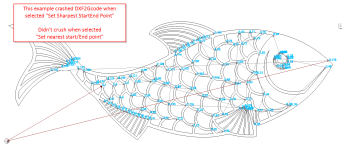

Then with TSP optimization ON - path becomes much better on the large scale.

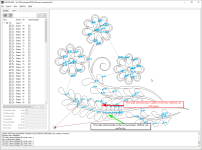

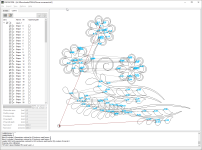

But if I zoom in to the portion from the first screenshot

You can see it did a much better job in optimization for cut (not intentionally) in the lower portion of the toolpath.

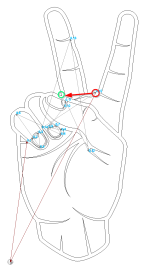

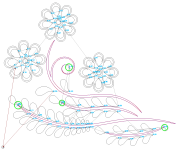

So in the end, if I go and manually select the shapes and hit "Set nearest Start Point", the tool path becomes optimized in the way that allows for 100% cut lines.

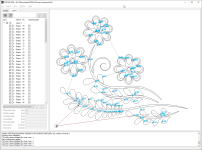

Full animated gif link of the process

Full animated gif link of the process

It took me about a long while to figure out the workaround. I even played with blade offset and such

Spent a lot of time playing with TSP parameters, until realized that it just looks for shortest. Obviously.

Do you think it is possible to prioritize the peaks (not shortest possible path through the line) when optimizing in drag knife mode, with or maybe without TSP?

On the first screeshot, when file just opened, some of the paths do start and end in a peak. Sorry I don't know what would be the proper name for this area of the path.